I am no longer captain of my ship and I am back to being maintenance boy with a long list of problems that need resolving.

We have already spoken to the marina who have been incredibly accommodating and will send a team of people to see us in an hour or so.

In the interim I decide to take a trip to the top of the mast, to try and understand why we had the chafe on our green spinnaker halyard. I take a look and a number of pictures but it is difficult to see what has caused it.

I am thinking that on the way down I could swap out the spreader lights, one of which is slightly faulty – still working but not as bright. That is a forlorn hope and I don’t get round to it!

I have now looked at the boom block and how it was positioned and know why this happened. Youtube and the internet isn’t always your friend and I should have checked this earlier rather than after eight hours of fantastic twin headsail sailing at 8+ knots. Still a new block is a small price to pay and we think the sheet for the headsail can be cut and still retain enough length to be used properly. The problem appears to be where I attached the block, which was as far back on the boom as I could get it. This meant that it was slightly obstructed by the main sheet blocks which meant it didn’t deploy properly and was at an angle. This resulted in the block being mangled by the rubbing of the sheet and damage from this to the line itself.

Probably most importantly is to try and sort out the Whitlock drive system, this could be as easy as a loose bolt in the workings that is obstructing the gears. Anyway fingers crossed.

While I am messing about with the steering I may as well check whether there is excessive play in the steering, which would have made the autopilot work harder.

So first up is the rigging. Firstly let me introduce our rigger. The marina have sent their rigging expert, Laureano Wizner. It was only afterwards that they asked me if I knew who he was: a former European sailing champion and americas cup contestant. At that stage, we thought he was just a really good rigger! Laureano climbs our 70 foot mast like a monkey jumping from section to section, checking our rig as he goes. I watch open mouthed. We do quite a bit while he is up there including setting up the sail so that he can see exactly what happens. He comes down with lots of photos and an explanation. Apparently the green halyard is rubbing against the top drum of the headsail. We discuss what can be done but actually the simplest solution is to use the red halyard which has suitable clearance, as checked when Laureano jumped up the mast again. He takes away our two lines to be cut and sorted out. When he returns he has also used the core of our dyneema lines and spliced these into two large circles which are to be threaded through the hoops in the boom for our block to stop the problem with the block not deploying correctly. A simple and elegant fix and a man talented enough to knock that up really quickly. In fact the whole thing is fixed in an afternoon and accompanied by a ridiculously cheap bill! I also go to the chandlery to buy replacement blocks and we are back ready to downwind sail.

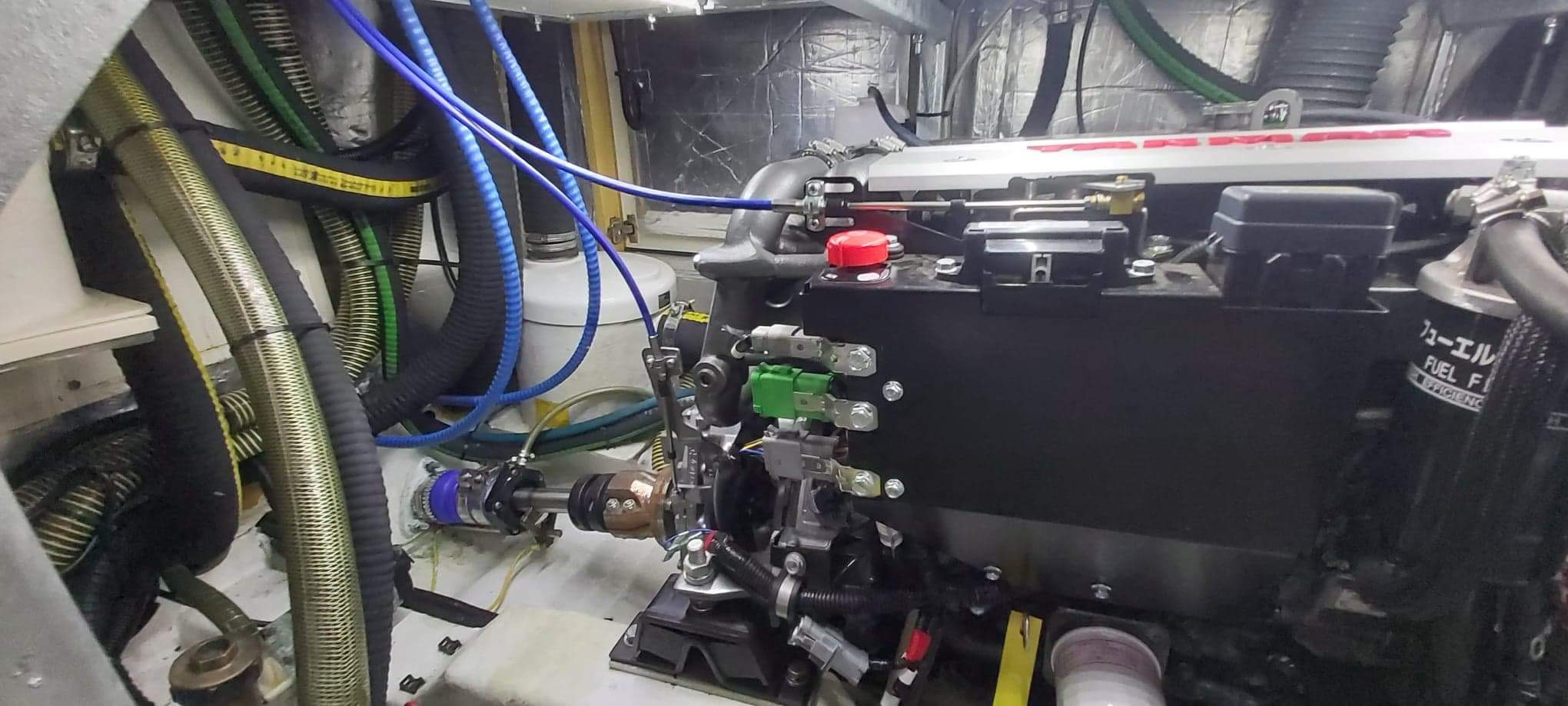

Onto the Whitlock drive to hopefully stop us having to hand steer the whole way. I have spoken to the expert in Southampton. The problem could be a loose screw that has dropped into the gears and is blocking the wheel turn although this would not usually stop it in exactly the same place every time. Still we can hope. Cliff sends me detailed instructions including photos of how to disassemble the drive and get to the inner workings, it doesn’t look to difficult so let’s give it a go. Firstly, I will need to extract the mechanical part of the autopilot. This piece of equipment is held by four bolts to a metal plate which is itself bolted to the hull. Initially I decide to undo the large bolts holding the plate to the hull. Two of these move easily enough, simultaneously moving the almost inaccessible nut under the plate. But I can get these sorted. The other two will not budge. I intend to use my new torque wrench but then notice that it is a half inch rather than the 3/8 for my socket set – that will be an adapter on the shopping list! I speak to the yard who helpfully cut a metal pole to act as an extension and provide greater leverage. This works and now I have the heavyweight plate loose. On to the four smaller bolts that hold the Whitlock drive to the plate. The first takes a bit of pressure but eases and we are going. Unfortunately the second isn’t budging until finally it does, as it sheers quarter of an inch down the thread – great. Another problem but I will come back to that. Bolt three helpfully does exactly the same, double great and just my luck. The fourth bolt actually comes out as it should and we are close. The electrical side is very simple, there are two pairs of wires one providing power and the other the control from the autopilot. These are live/neutral pairs so having marked one set with tape to connect them up correctly, I set about removing these. Now I have the, really quite heavy, drive out of the lazarette. We can now see what we have to deal with. It is exactly the same as the pictures that i have so once I can resolve the two sheered bolts removing the plate will be a cinch!

I have asked the yard if it is possible to use one of their benches to do the work which promises to be quite messy and ingeniously gives my access to a large number of curious Spanish engineers who may be able to help. Unfortunately that doesn’t work out as despite using corrosion x and wd40 to try and break the corrosion locking the bolt to the case and cutting a slot into the bolt with an angle grinder, we still can’t free the bolts. It is time to call professional help. Unfortunately, the mechanic isn’t available til the next day which means we have another day to wait rather than the single overnight we had hoped for. We are now being significantly delayed with no guarantee of fixing the problem. It will be a real shame if our planned 1,500 mile journey in two weeks is reduced to less than half of that!

The next day the mechanic arrives at just after 9am. I explain that I would like to work with him so I can understand it and he says no problem, he will give me a call about 11ish and I assume that he has something to work on first. Just after 11am I get the call that the mechanic is ready for me. I arrive in the yard where he has set up an impromptu workbench in the back of his van. The Whitlock is already in bits but now he needs the detailed instructions on my iPad to get into the workings. I am pleased with his success and I believe he used a torch to superheat the bolt to break its seal before using mole grips to undo it but I am guessing. Anyway we get into the workings and the culprit is clear. There is a chain that drives the arm that attaches to our steering, this is controlled by some gears and the sprocket on this has two teeth missing. He has located one of them in all of the gunk but this part needs replacing. I am quickly on the phone to Cliff who is really helpful. He has the exact same drive on his shelves which was water damaged and this caused the electronics to stop working. It was two weeks old at the time. He will tear it apart retrieve the sprocket and send it to me. All at a very reasonable price. This is fortunate since he has informed me that a replacement would be over £9,000 (This was a mistake since I had confused matters by thinking it was a higher spec model – in the end the replacement would be a shade over £2,000, a paltry two boat tokens, almost cheap!). However, this will take time and then it needs to be shipped to me in Spain in a post brexit world. Clearly, we are going to be hand steering for a little while. The mechanic has taken half of a day with two of them to do this work and he kindly boxes it up for me ready for when I have the spare delivered.

We are as far as we can go but the rig is fully functional and we have a plan for the autopilot. A plan that doesn’t fill us with joy but a plan all the same.

Now for the dreaded part, the bill. We have had immediate attention from all services in the yard and I can’t speak highly enough about how professional and helpful the team are at Davila marina, Vigo. I would recommend it to anyone needing post Biscay maintenance and let’s admit it, this is probably a fair few of us. The mechanic had two of them working on it for several hours and was a shade over €100, the brilliant rigger was double that and again we had a few of them working for hours sorting us out. Everywhere else I have been the bill would have been double or triple that! You would also have been lucky to get anyone to look at it for a few weeks. Thank you for the fantastic facilities and brilliant people at Vigo!

The headsail was the same Yankee cut that we had originally, we had explored making this larger but in the end we agreed to stay as we were. As for the main, we did not have vertical batons in our furling main. We have seen these on other M54 but at least one had significant issues with furling the main and we were happier not adding to the risk of a sail jam potentially at the risk of a little performance.

The headsail was the same Yankee cut that we had originally, we had explored making this larger but in the end we agreed to stay as we were. As for the main, we did not have vertical batons in our furling main. We have seen these on other M54 but at least one had significant issues with furling the main and we were happier not adding to the risk of a sail jam potentially at the risk of a little performance.  Finally, we agreed that we wanted storm sails for heavy weather, although our staysail is about the same size as the largest storm sail. It helped us define a smaller storm sail which should mean we have sails for all conditions, although we don’t expect to be out there in bad weather by choice!

Finally, we agreed that we wanted storm sails for heavy weather, although our staysail is about the same size as the largest storm sail. It helped us define a smaller storm sail which should mean we have sails for all conditions, although we don’t expect to be out there in bad weather by choice!

There we’re some features of the old panel we liked such as the outline of the Moody with indicators for the lights being on. However, these no longer worked when we went to LED because of the lower draw of power. A simple change however. This would also provide an opportunity to remove the extra standard horizon chart plotter as part of the navigation overhaul, discussed elsewhere, and also give us room for an SSB.

There we’re some features of the old panel we liked such as the outline of the Moody with indicators for the lights being on. However, these no longer worked when we went to LED because of the lower draw of power. A simple change however. This would also provide an opportunity to remove the extra standard horizon chart plotter as part of the navigation overhaul, discussed elsewhere, and also give us room for an SSB.

Maria got some top quality advice on how to do this by cleaning up using

Maria got some top quality advice on how to do this by cleaning up using  Not least of all because of the alternator shaped imprint on your chest from having to lean on it for so long stretching to dry off the bilge. Interestingly, the mess looked worse than it was with the oil mixed with water. Not so bad an oil problem but the water is another problem we need to resolve. After quite some time, the bilge is squeaky clean which is also a shame because I know it will get messy again. To make sure I know where the leak is coming from I lay down two puppy pads face up under the engine which will hopefully catch the oil and give a view as to where it is coming from. The running of the engine is for another day though since we want to make sure that we don’t have a leak when the engine is cold. So next up is cleaning out the bilges of any water. This could be from condensation, rainwater seeping in around the mast or from a problem with the deck drains or a problem with a through hull or pipe. All will need checking out.

Not least of all because of the alternator shaped imprint on your chest from having to lean on it for so long stretching to dry off the bilge. Interestingly, the mess looked worse than it was with the oil mixed with water. Not so bad an oil problem but the water is another problem we need to resolve. After quite some time, the bilge is squeaky clean which is also a shame because I know it will get messy again. To make sure I know where the leak is coming from I lay down two puppy pads face up under the engine which will hopefully catch the oil and give a view as to where it is coming from. The running of the engine is for another day though since we want to make sure that we don’t have a leak when the engine is cold. So next up is cleaning out the bilges of any water. This could be from condensation, rainwater seeping in around the mast or from a problem with the deck drains or a problem with a through hull or pipe. All will need checking out.  Maria has bought a cheap

Maria has bought a cheap  We also have some water down by the keel bolts and this is soon gone. Finally, Maria decides that the grey water box is going to be spotless! First clean out the dirty water and then clean the box which looks amazing. Just fill it with water to make sure that switch is working well and….. nothing… no pumping at all. Maria starts to apologise for cleaning our new switch and breaking it but it can’t be that. I check the connectors and everything seems fine, give them a little wiggle and the pump jumps to live. Right so a loose connection, quickly traced to the live wire. Firstly, I try to reuse the existing connector by bending it back using the new crimping tool, why do we try to botch these jobs? Eventually, common sense prevails and I decide to put a new connector on it.

We also have some water down by the keel bolts and this is soon gone. Finally, Maria decides that the grey water box is going to be spotless! First clean out the dirty water and then clean the box which looks amazing. Just fill it with water to make sure that switch is working well and….. nothing… no pumping at all. Maria starts to apologise for cleaning our new switch and breaking it but it can’t be that. I check the connectors and everything seems fine, give them a little wiggle and the pump jumps to live. Right so a loose connection, quickly traced to the live wire. Firstly, I try to reuse the existing connector by bending it back using the new crimping tool, why do we try to botch these jobs? Eventually, common sense prevails and I decide to put a new connector on it.  Unfortunately the small box of connectors I have is in the toolkit in the motorhome. I ask Maria to pass me the keys without being clear and neither of us check, it is only after I have walked a couple of hundred metres to the far car park that I glance into my hands to find the keys for the land cruiser. Ok, all the way back, ask for the right set of keys, both of us check it and I return to the motorhome. Pull out the old crimper, you can’t have too many, and the small box of electrical terminators. It is only as I return to the pontoon clutching these that I recall that I bought a big box of terminators which is in one of the spares areas on the boat and I already have a much better crimper on the boat! So that is 30 minutes of my life I will never get back. On my return, Maria says she thought it was strange that I wasn’t using the ones on the boat…. bless her for not mentioning it! New terminator and industrial crimper later and we have a positive connection that looks good. Quick pull on the wires to check and the negative comes off in my hands. Seconds later that one is done too and everything is working as it should.

Unfortunately the small box of connectors I have is in the toolkit in the motorhome. I ask Maria to pass me the keys without being clear and neither of us check, it is only after I have walked a couple of hundred metres to the far car park that I glance into my hands to find the keys for the land cruiser. Ok, all the way back, ask for the right set of keys, both of us check it and I return to the motorhome. Pull out the old crimper, you can’t have too many, and the small box of electrical terminators. It is only as I return to the pontoon clutching these that I recall that I bought a big box of terminators which is in one of the spares areas on the boat and I already have a much better crimper on the boat! So that is 30 minutes of my life I will never get back. On my return, Maria says she thought it was strange that I wasn’t using the ones on the boat…. bless her for not mentioning it! New terminator and industrial crimper later and we have a positive connection that looks good. Quick pull on the wires to check and the negative comes off in my hands. Seconds later that one is done too and everything is working as it should. On this occasion, lifting the floorboard and the metal lifter comes off in our hands! This was obviously after Clyde had woken up! Right, longer screws required which is where my reputation as a hoarder comes in well. I have a box of assorted screws, bolts, nuts and washers collected over time. Of course the one I am looking for takes some searching but it was never in doubt that I would be able to find one that sorted this latest problem out.

On this occasion, lifting the floorboard and the metal lifter comes off in our hands! This was obviously after Clyde had woken up! Right, longer screws required which is where my reputation as a hoarder comes in well. I have a box of assorted screws, bolts, nuts and washers collected over time. Of course the one I am looking for takes some searching but it was never in doubt that I would be able to find one that sorted this latest problem out.

This was Vanessa, who had done some work for some friends of ours, which had been good quality. However, she is busy which could be a good sign but will m ana delay. Maria spoke to her and described what she wanted. It did take longer than we expected but we are really happy with the results, which exactly match our cockpit cushions since James had kindly told us the material and colours. The simple design works really well the fold means that we can expose the hatch for the aft cabin, allowing more air in or as a food or drinks table when you are on the sunbed. Flipping it the other gives a standing area which is often where I am when steering via the autopilot because the visibility is so good.

This was Vanessa, who had done some work for some friends of ours, which had been good quality. However, she is busy which could be a good sign but will m ana delay. Maria spoke to her and described what she wanted. It did take longer than we expected but we are really happy with the results, which exactly match our cockpit cushions since James had kindly told us the material and colours. The simple design works really well the fold means that we can expose the hatch for the aft cabin, allowing more air in or as a food or drinks table when you are on the sunbed. Flipping it the other gives a standing area which is often where I am when steering via the autopilot because the visibility is so good.

The wiring had melted. We had this once before in the aft cabin where the wiring for the davits came into the boat. On this occasion it was some corrosion within the wiring that had caused the problem.

The wiring had melted. We had this once before in the aft cabin where the wiring for the davits came into the boat. On this occasion it was some corrosion within the wiring that had caused the problem. There was also quite a bit of surface rust of the bow thruster too which in an area that is mostly dry seemed strange – maybe reinforcing our theory about the fire.

There was also quite a bit of surface rust of the bow thruster too which in an area that is mostly dry seemed strange – maybe reinforcing our theory about the fire.